Blog

How to Choose the Right Stainless Steel Woven Wire Mesh?

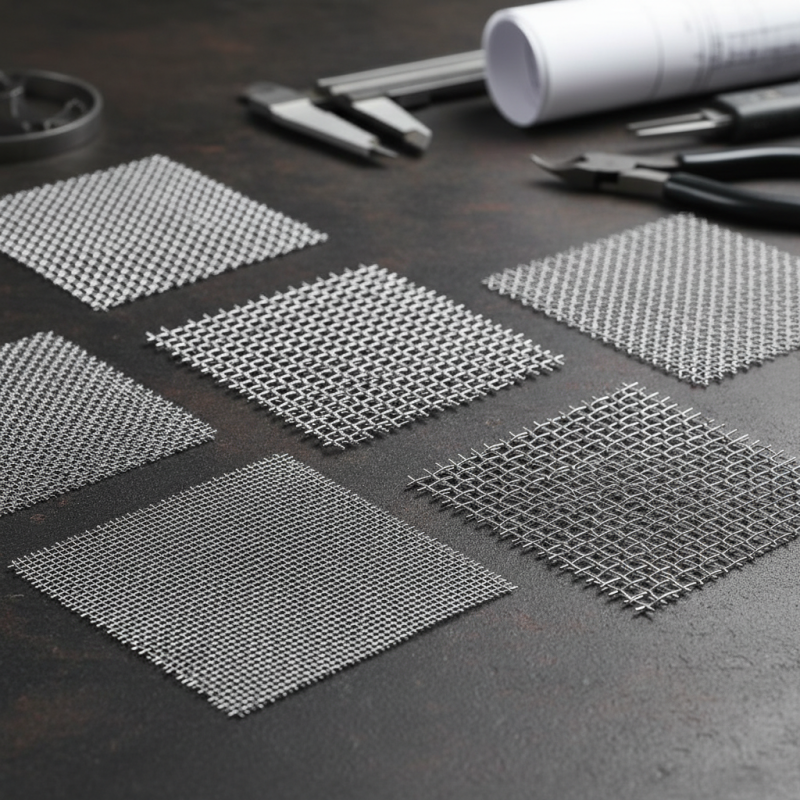

When selecting the right stainless steel woven wire mesh, several factors come into play. This material is renowned for its strength and versatility, making it a popular choice in various applications. However, its wide range of specifications can sometimes confuse buyers.

Understanding the key aspects of stainless steel woven wire mesh is essential for making an informed decision. The mesh type, wire diameter, and weave pattern all influence the overall performance. For example, a tighter weave may provide better filtration but could be more expensive. One must consider the specific needs of the project to avoid overspending or compromising quality.

It's easy to overlook minor details that impact functionality. Choosing the wrong mesh might lead to unexpected issues down the road. Perhaps it’s a specific application that requires a durable, corrosion-resistant material. Reflecting on these elements will guide you toward the most suitable stainless steel woven wire mesh for your needs.

Factors to Consider When Selecting Stainless Steel Woven Wire Mesh

When selecting stainless steel woven wire mesh, consider several key factors. The wire diameter is crucial for strength and durability. Thicker wires provide better support, while thinner wires offer more flexibility. Evaluate the mesh opening size too. Larger openings allow greater airflow, while smaller openings offer better filtration.

Next, think about the environment where the mesh will be used. For instance, certain grades of stainless steel resist corrosion better than others. If the mesh will be exposed to harsh chemicals, choose a suitable grade. Additionally, the weave pattern affects both the aesthetics and functionality. A twill weave provides a tighter hold, whereas a plain weave is more straightforward but may not be as strong.

Remember, price often reflects quality. A lower cost may mean inferior materials. However, that's not always the case. Some affordable options could perform well. Missing out on essential details like these can lead to poor choices. Therefore, weigh each factor carefully before making a decision.

Factors to Consider When Selecting Stainless Steel Woven Wire Mesh

Common Applications of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh sees wide application across various industries. In food and beverage production, it is crucial for filtration and safety. The mesh prevents contamination while allowing liquids to flow freely. In architecture, it adds a unique aesthetic appeal. Architects often use it for facades and decorative screens, enhancing both functionality and beauty.

In industrial settings, stainless steel wire mesh serves numerous purposes. It is popular in mining and aggregate industries for separating materials. The durability of stainless steel withstands harsh conditions, ensuring longevity. In filter elements, it plays a vital role in air and fluid filtration. Yet, some users overlook the importance of choosing the right aperture size, which may affect efficiency.

Additionally, the automotive sector employs stainless steel mesh in exhaust systems. In this case, it improves the flow of gases, ensuring cleaner emissions. However, selecting the wrong type can lead to increased maintenance. It’s essential to assess specific needs. Users may sometimes underestimate the local environment’s impact on material performance. Weather resistance is key in many applications.

Understanding Different Grades of Stainless Steel for Wire Mesh

Choosing the right stainless steel woven wire mesh can be challenging. Understanding the different grades of stainless steel is crucial. Common grades include 304, 316, and 430. Each offers unique properties suited for different applications.

Grade 304 is a general-purpose steel, good for corrosion resistance. It is widely used in food processing and kitchen equipment. However, in harsher environments, it may not hold up well. Grade 316 has higher corrosion resistance. It handles saltwater and chemicals better, making it a preferred choice for marine applications. Yet, it can be more expensive and harder to source.

Grade 430 is magnetic, making it less suitable for some applications. It is often used in decorative items and automotive applications. Remember that each grade has its strengths and weaknesses. Consider the environment where the mesh will be used. This awareness can prevent costly mistakes. Balancing cost and performance is key to making the right choice.

Evaluating Wire Diameter and Mesh Opening Size

When choosing stainless steel woven wire mesh, wire diameter and mesh opening size are crucial. The wire diameter impacts strength and flexibility. Thicker wires offer durability. However, they may limit airflow. Thinner wires allow better flow but can be less robust. Finding the right balance is essential based on your application needs.

Mesh opening size refers to the space between the wires. Smaller openings filter finer particles. Larger openings provide better visibility and airflow. Yet, larger openings might not retain small contaminants. Selecting the wrong size can lead to insufficient filtration or excessive pressure loss. This decision requires careful thought about specific requirements and potential trade-offs.

Consider testing different combinations. Observing how each performs can provide clarity. It's easy to overlook these details, but they play a vital role in the mesh's effectiveness. Sometimes, the best choice isn't the most obvious one. Reflect on your project goals and choose wisely.

How to Choose the Right Stainless Steel Woven Wire Mesh? - Evaluating Wire Diameter and Mesh Opening Size

| Wire Diameter (mm) | Mesh Opening Size (mm) | Applications | Typical Uses |

|---|---|---|---|

| 0.5 | 1.0 | Filtration | Water treatment, chemical filtration |

| 1.0 | 2.0 | Construction | Reinforcement in concrete |

| 1.5 | 4.0 | Protection | Safety barriers, fencing |

| 2.0 | 6.0 | Culinary | Cooking utensils, food processing |

| 3.0 | 8.0 | Automotive | Filter screens, grille meshes |

Comparing Cost and Quality in Stainless Steel Woven Wire Mesh Options

When choosing stainless steel woven wire mesh, cost and quality go hand in hand. Different grades of stainless steel offer various levels of corrosion resistance. For example, 304 stainless steel is often cost-effective but may not withstand harsh environments like marine settings. On the other hand, 316 stainless steel, while pricier, provides superior protection against saltwater and chemicals. Consider your specific application when weighing these factors.

Quality also varies significantly among woven wire mesh options. The construction and weave pattern influence its overall durability. A tighter weave can enhance strength, but it may come at a higher price. Sometimes, cheaper options sacrifice this, leading to potential issues down the line. You might find yourself pondering the balance between upfront costs and long-term value.

Investing in higher-quality stainless steel could save money in the long run. Cheaper alternatives may need frequent replacement. It's wise to ask yourself whether saving a few dollars upfront is worth it. Reflect on your needs, the environment, and how the mesh will be used. Each decision shapes the outcome. Ultimately, taking the time to analyze cost versus quality is essential for making an informed choice.

Article Source:

Tell us about your project

Our Off-grid experts will come back with recommendations